By keeping a close eye on finished goods inventory, you can optimize storage utilization and minimize unnecessary expenses. Finished goods inventory is a fundamental principle that applies to all e-commerce businesses, regardless of whether you’re selling apparel, electronics, or sporting goods. By effectively managing your finished goods inventory, you can streamline your fulfillment process, delight your customers, and propel your online store towards long-term success.

Step-by-Step Calculation Process

Code 8069 applies to stores principally engaged in the retail selling of cellular telephones, smartphones, pagers and calling cards. Also includes the activation or renewal of cellular telephone service plans, and incidental service or repair. These stores may also sell an incidental amount of related cellular telephone accessories such as battery chargers, faceplates, skins, headsets, carrying straps and cases. For the past 52 years, Harold Averkamp (CPA, MBA) hasworked as an accounting supervisor, manager, consultant, university instructor, and innovator in teaching accounting online.

Set up demand forecasting

Accurate demand forecasting helps ensure you have optimal inventory levels. To predict future demand and adjust production schedules, use historical sales data, market trends, and advanced analytics. At this point, you also anticipate peak seasons or holiday sales times to decide when you need to increase production to meet customer needs without risking overstocking. This process ensures the right amount of finished products is available to meet customer needs without overburdening the storage space or cash flow. Predicting demand accurately is key to reducing excess inventory costs and improving customer satisfaction. Another reason why finished goods inventory management is paramount is that it leads to optimal sales and capital allocation.

Direct cost Vs. Indirect Cost – What are the Key Difference?

- The painting of traffic lines in parking lots after the paving or repaving is completed by the same contractor is inclusive under this classification.

- By calculating the finished goods inventory, you can know how much inventory is needed for the production process and stockout.

- Finished goods inventory includes products that have been fully manufactured and are ready to be sold.

- Efficiently managing this inventory helps companies meet customer demand, optimize stock levels, and avoid lost sales opportunities.

- Your employees must understand how to use your inventory management tool effectively.

Another operation contemplated under this classification is the erection of concrete slabs using the “lift” method. This operation involves the pouring of concrete slabs on the ground and then hoisting them to the top floor using hydraulic jacks to position columns which will hold up each floor. When the floors are lifted to the correct height, steel beams will be installed to hold up the concrete floors. Clubs generally fitting the above description include business, social and athletic clubs in addition to fraternal societies or orders such as the Knights of Columbus, the B.P.O. of Elks and Masonic lodges. These clubs may have extensive or limited facilities and services depending upon the type of club.

A third approach, FEFO or ‘First-Expired, First-Out,’ ensures that items that are approaching their expiry date are out the door first. Understanding the difference between finished goods, raw materials, and WIP is important. Raw materials are the unprocessed resources used in manufacturing, while WIP items are those that are still in the production process. Finished goods inventory management methods are the finished goods accounting procedures and practices manufacturers use to track, control, and optimise inventory stock of finished products that are ready for sale. The finished goods inventory measure is important for accounting purposes because it represents current assets and potential profit for your business. It also helps you to manage your supply chain and avoid material waste by tracking how long it takes to produce a product.

The mixture is then poured or pumped into molds that are shaped in the form of crayons. After the cooling period is completed, labels are attached to the crayons. Our robust system tracks inbound, outbound, and in-progress stock in real-time, eliminating data silos and providing a single, crystal-clear view of your finished goods inventory across all locations. This transparency empowers you to make informed decisions about production, fulfillment, and future purchases. Overstocking can lead to excessive storage costs and the risk of obsolescence.

Fur or felt body hats are cut, sewn, steamed or blocked in presses and trimmed. Accessories may be added such as flowers, ribbons, bands, fur or feathers. Hats made from textile may be embroidered or screen printed with the employer’s designs, artwork or logos. This classification includes the repair of watches principally performed for dealers. This classification does not apply to cleaner/debris removal employees working in conjunction with the tradespersons.

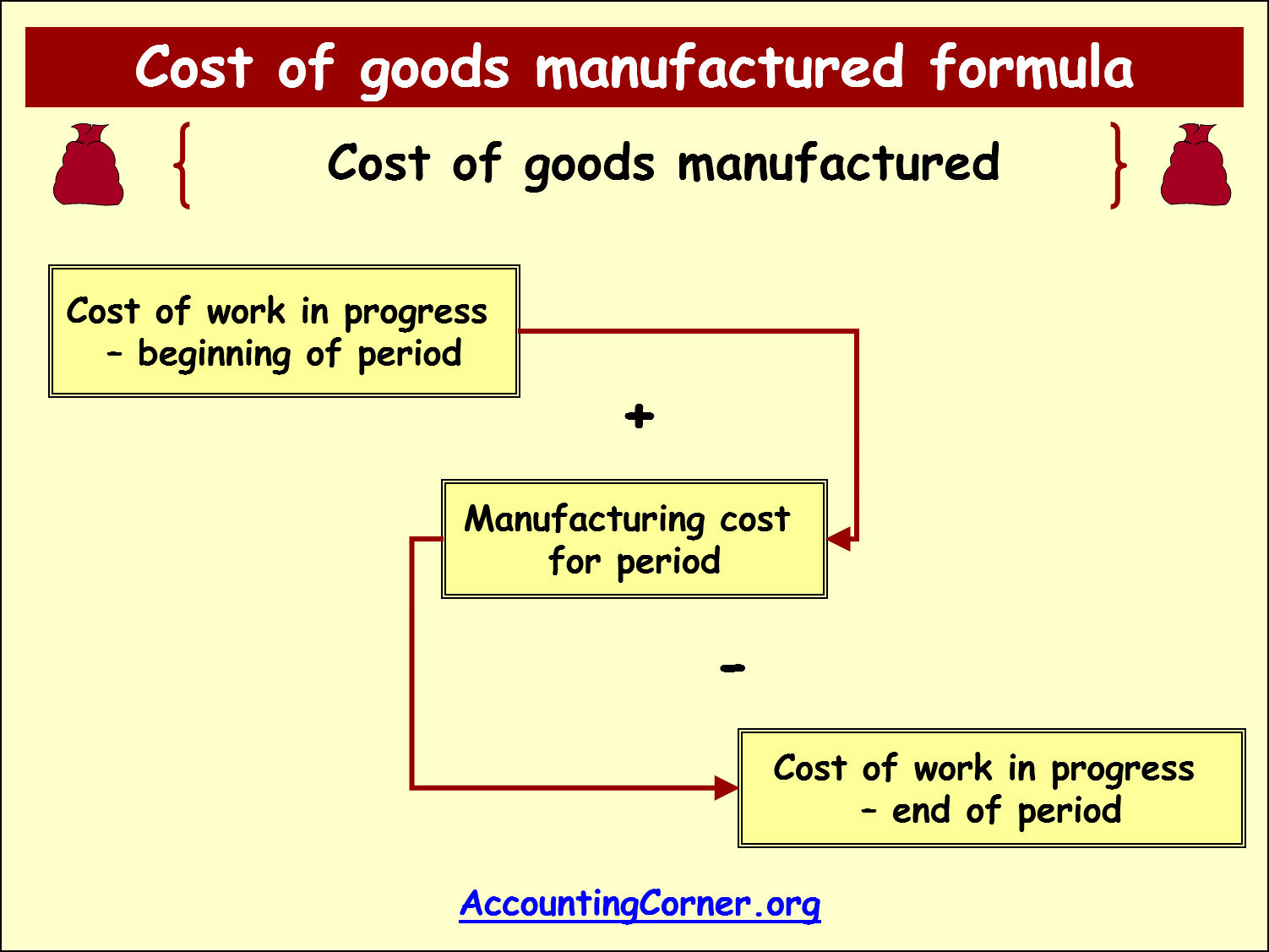

As you can see, this process allows a manufacturer to track how much inventory it has at any stage in the production process. At the end of a period, these three categories of inventory are usually stated separately on the balance sheet, so investors and creditors can understand the value of the inventory. In other words, finished goods are usually worth much more than raw materials.

Whether you’re a small business or a large corporation, there’s nothing worse than a customer hitting that “buy now” button, only to be met with the dreaded “out of stock” notification. Consider this blog your action plan for learning how to calculate finished goods inventory. Finished goods inventory is the number of inventory or manufactured items that are still available in the stock and that customers can still purchase.